Magnetic Welding Holder

Item No.: 5850

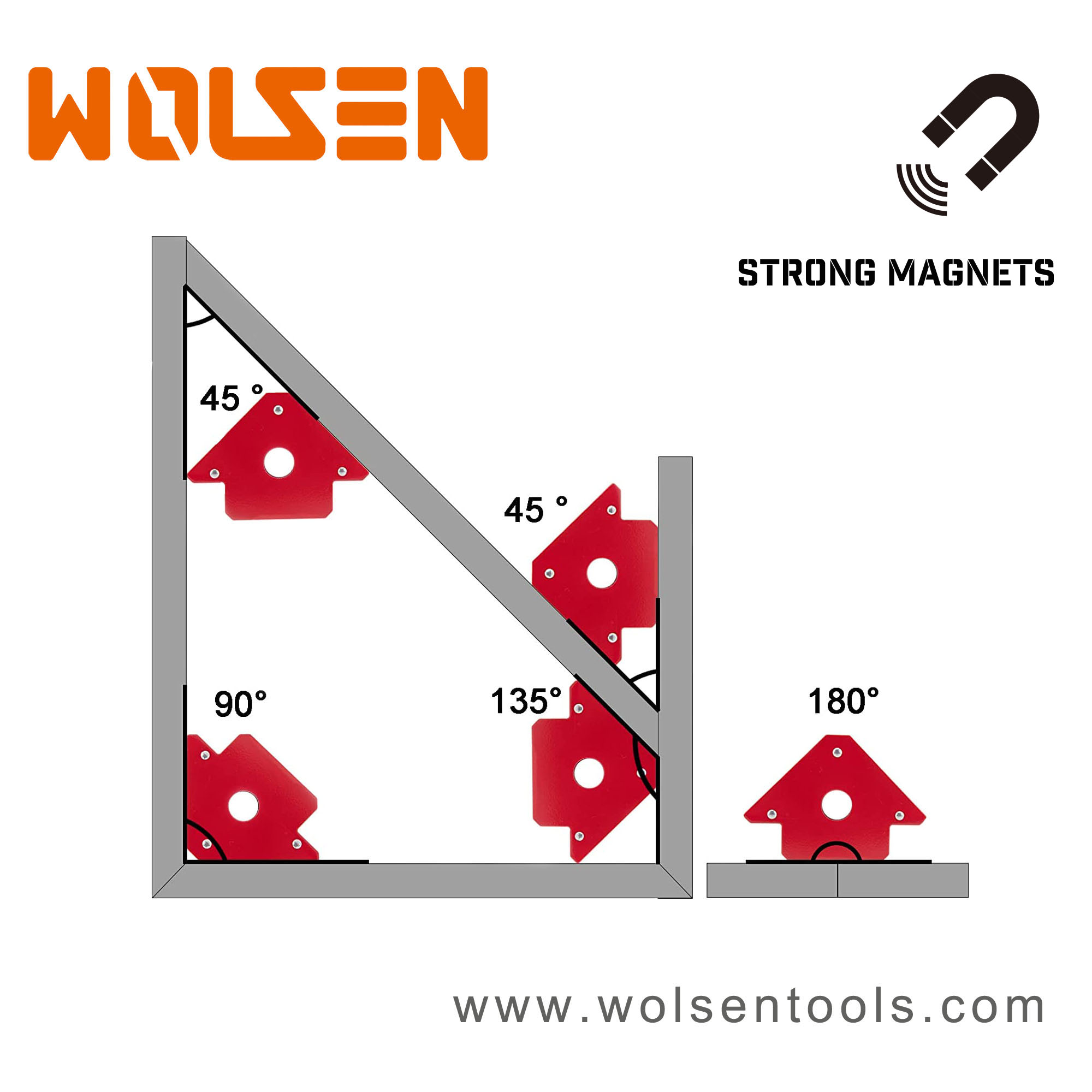

Working Angles: 45°, 90°, 135°

Magnetic Force: 25LBs, 50 LBs, 75 LBs

Surface Treatment: Spray Painted

Packaging: Double Blister

Made of quality steel sheet and strong magnet.

| ITEM NO. | CAPACITY | SIZE | WEIGHT | QTY./CARTON |

| 585025 | 25LBs | 83x15mm | 328g | 48 |

| 585050 | 50LBs | 102x17mm | 580g | 30 |

| 585075 | 75LBs | 122x25mm | 1014g | 18 |

Electric welders grab the magnetic welding holder easily by using the central hole.

Work at 4 different angles

Each holder provides 45°, 90°, 135° and 180° to support the materials at different angles to work.

What are magnetic welding holders?

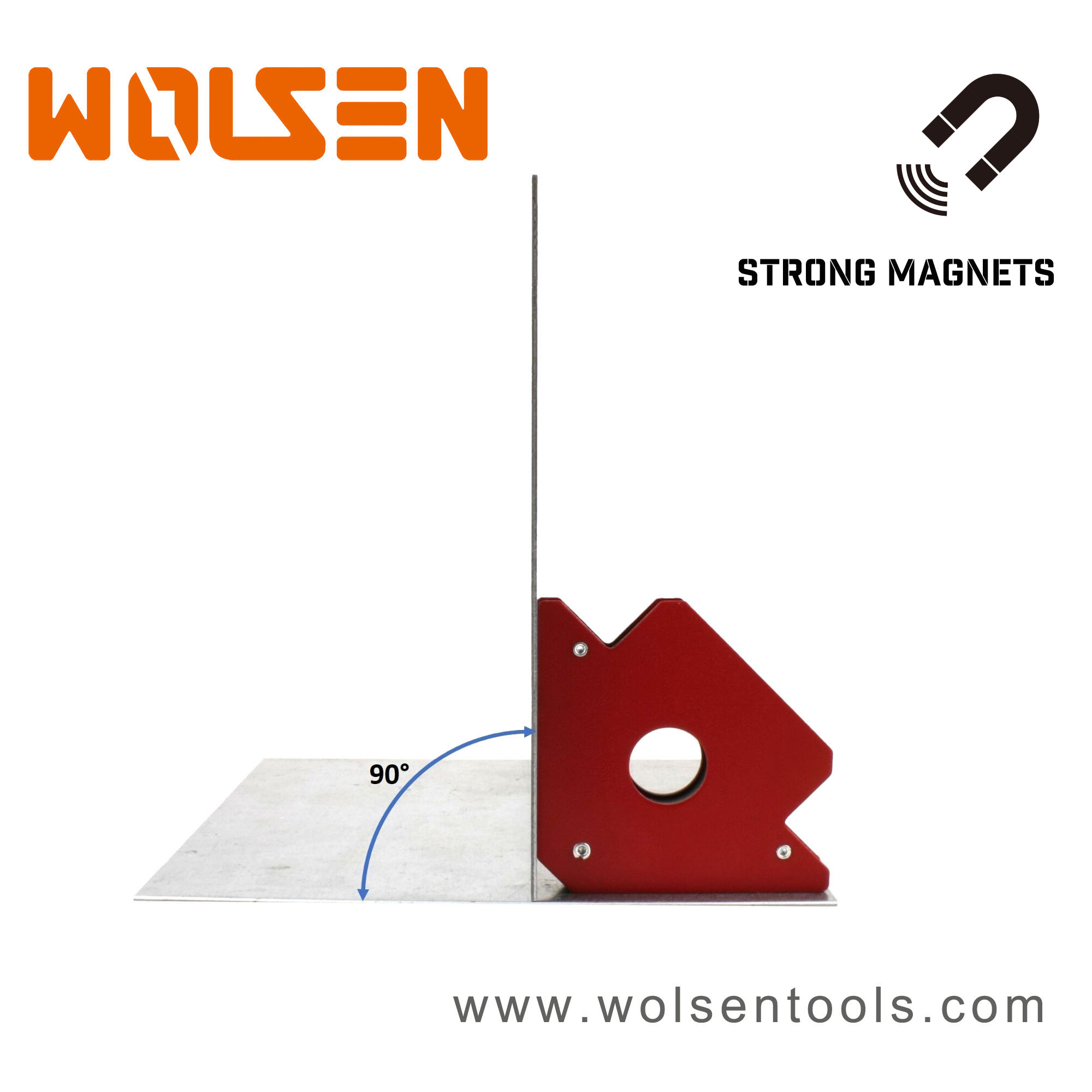

These welding holders grip metal and hold it at the angle you need to work safely and efficiently. The welding holders are compact with durable high gloss enamel end plates. Holds work at 45°, 90°, and 135° angles. Powerful magnets.

What is the purpose of a welding magnet?

Welding magnets are magnets with very high levels of magnetism that is used to hold workpieces together through its magnetic attraction so welders can weld, cut or paint the material. Welding clamps are devices that are designed to hold two or more parts together by pressing them together from opposite sites.

How does on off magnet work?

When in the OFF position, all of the magnetic attraction is somehow contained inside. It doesn’t stick to steel. Touch the bottom of the magnet to a steel surface that you want it to stick to, and turn the knob. Now it attracts with an incredibly strong force.

Can magnets be welded together?

The main reason why we should not be welding with magnets is that it would essentially ruin them. With the amount of heat that it can handle, it won’t be able to contain its structure. If you do weld a magnet together, most likely, it will burn up and be of no use to you after it is done.

What are magnetic clamps used for?

Magnetic clamps hold metals in place, firmly. Thus, welders can continue their work hands-free, thereby making the welding process safer and more efficient. It’s easy to set up a magnetic clamp, and it provides an accurate hold.

How does a magnetic tool base work?

The magnet, when it is rotated or pressed, acts as the ON/OFF switch for the magnetic base. It is the movement of the magnet which magnetises the iron, effectively switching the base on and off. When the poles of the magnet are lined up with the aluminium spacer, the magnet is OFF.